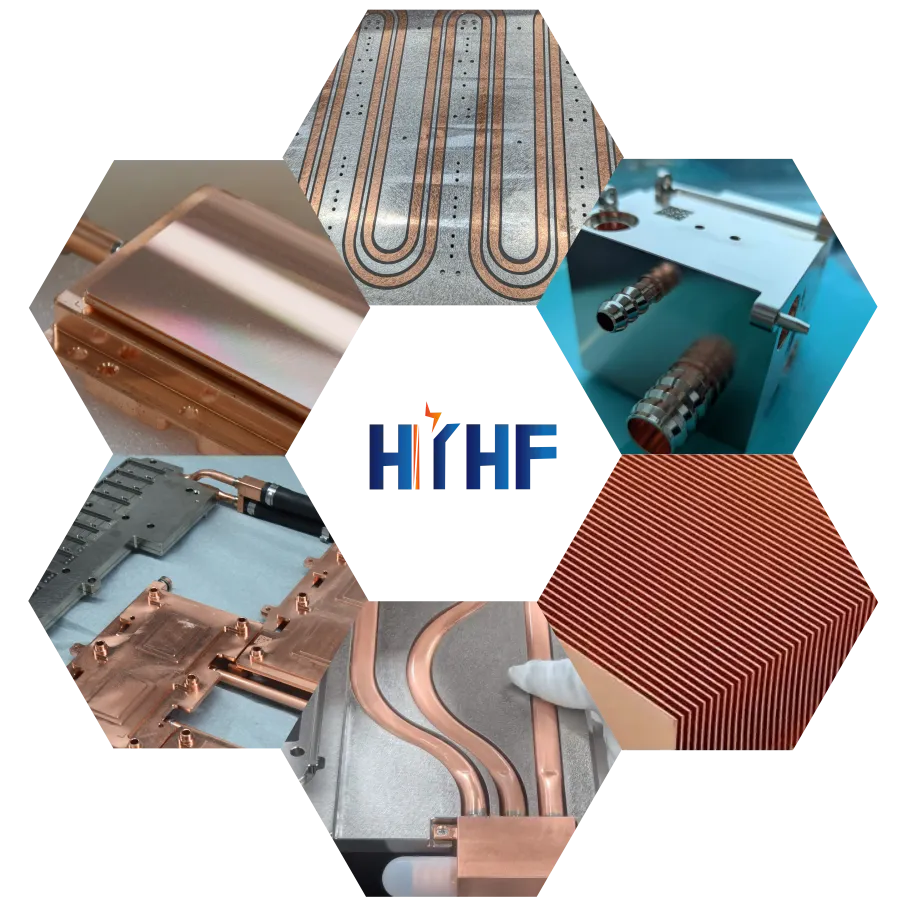

HYHF - Professional Liquid Cooling Component Manufacturer

One-stop liquid cooling component manufacturer

With nearly two decades of experience in manufacturing and processing precision thermal management components, we provide you with professional and high-quality services.

It has fully passed ISO9001/IATF16949 and other quality management system certifications, and has been continuously recognized as an innovative small and medium-sized enterprise and a high-tech enterprise; it also holds dozens of invention patents.

Precision manufacturing of liquid cooling heat dissipation components

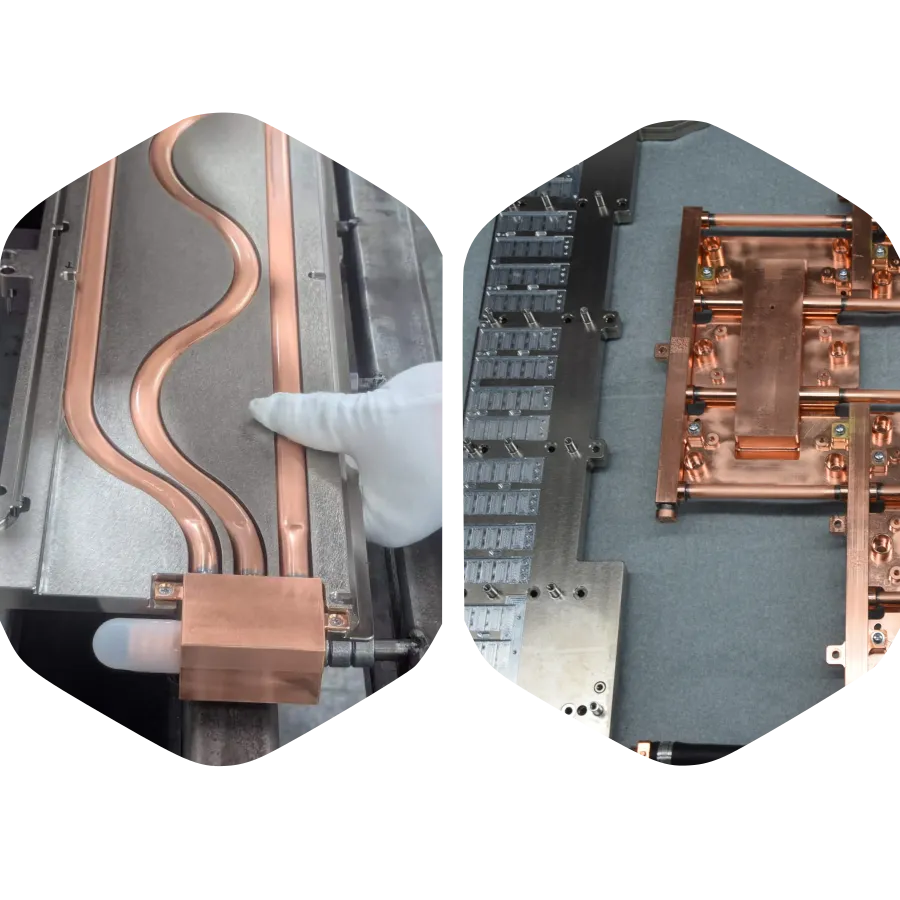

The liquid cooling system consists of core components such as cold plate assemblies, immersion assemblies, Manifold, and cabinets.

Customer application cases:

Currently, we mainly manufacture heat dissipation components such as liquid cooling plates, skived heat sinks, and deep hole drills for our customers.

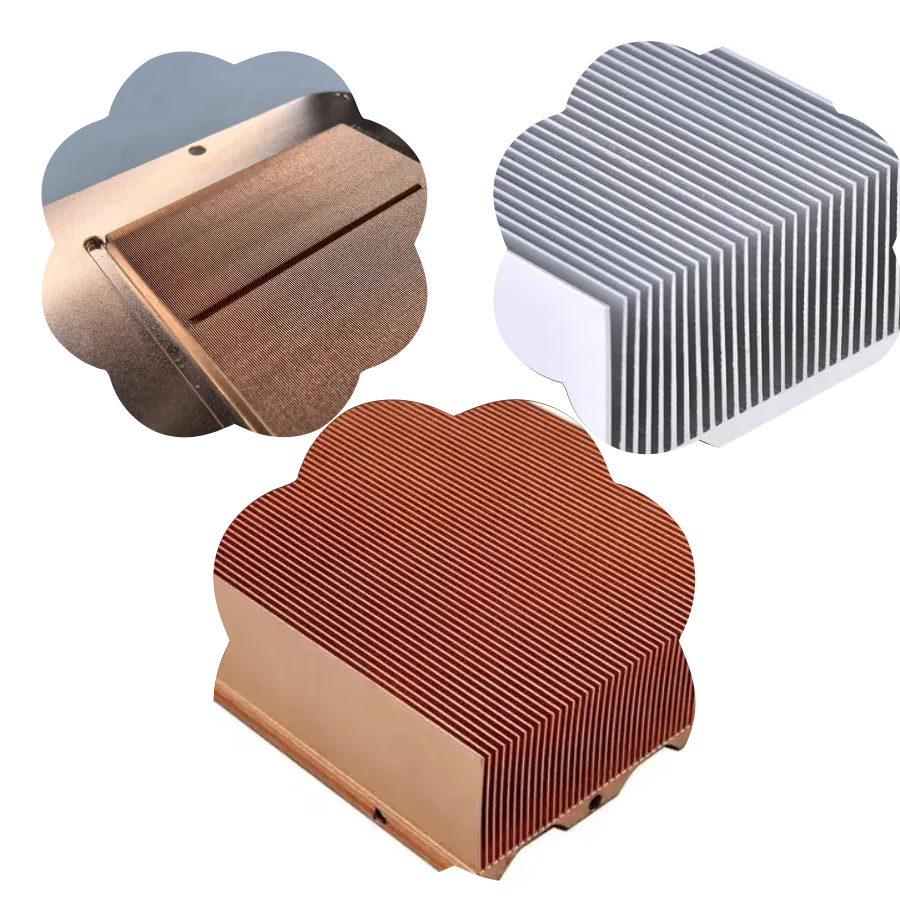

Skived heatsink

Core features:

The material used is CU1020 oxygen-free copper, which does not blister within two hours in a high-temperature welding furnace, ensuring high welding stability. The thinnest fin can be as low as 0.05mm, the tooth tolerance is 0.01mm, and the CNC sliding tolerance is 0.01mm, achieving top-tier performance in the industry for microchannel welding. CNC machining ensures the flatness and smoothness of the welded surface. The product undergoes anti-oxidation treatment, and cleanliness is checked using a Dyn pen.

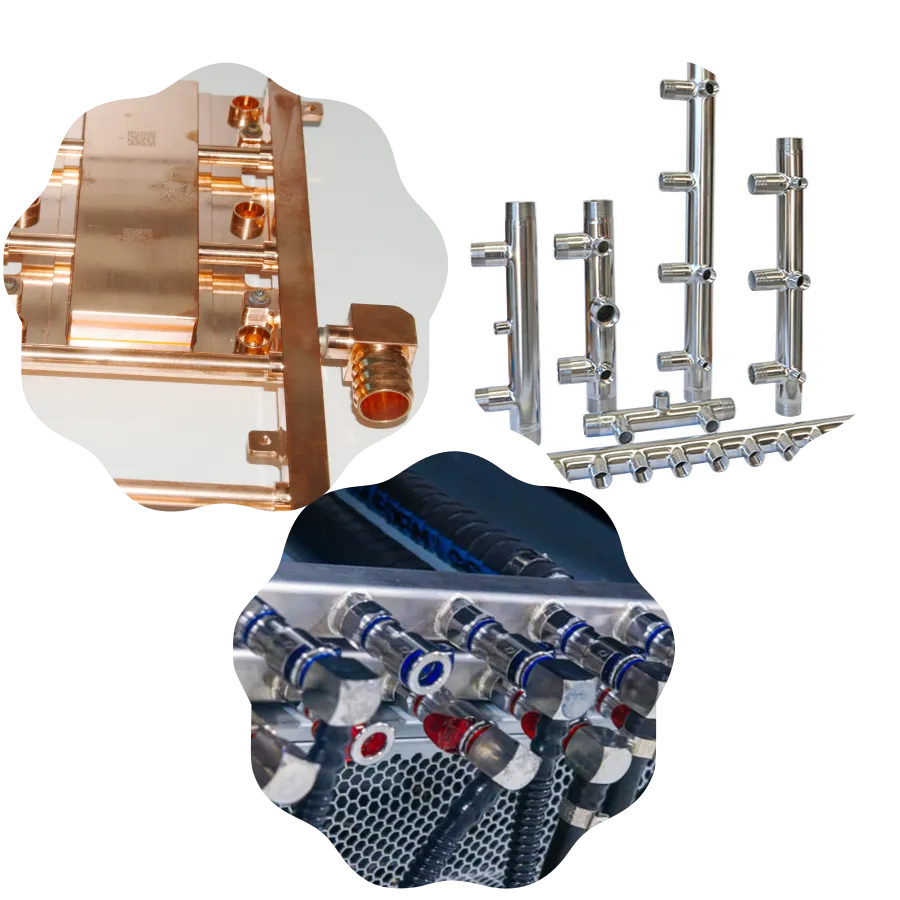

Deep hole drilling products

Key features:

The product uses CU1020 oxygen-free copper/stainless steel, exhibiting high stability during high-temperature welding. Deep hole drilling is used for machining holes; the tolerance within 4mm of the hole opening is 0.05mm, and other tolerances are guaranteed according to the drawing dimensions. The product undergoes anti-oxidation treatment to ensure the removal of particles and burrs from the holes.

Strategic Partners

Our partners are primarily focused on leading liquid cooling customers, including well-known clients such as AVC, FRD, and Envicool