Cold-forged radiator parts Fabrication

Cold-forged radiator parts Fabrication

Cold forging is a forming and forging technique for profiles below their recrystallization temperature (generally referring to room temperature). Cold forging materials are mostly aluminum and some alloys, copper and some alloys, which have low deformation resistance and good plasticity at room temperature. Cold forging can cause work hardening (strain hardening) in the profiles during processing, increasing their strength and hardness. Cold forging technology is widely used by radiator manufacturers in the production of light source component radiators and LED radiators, and is beginning to be applied in water-cooling solutions for high-voltage frequency converters, wind power converters, and motor controllers.

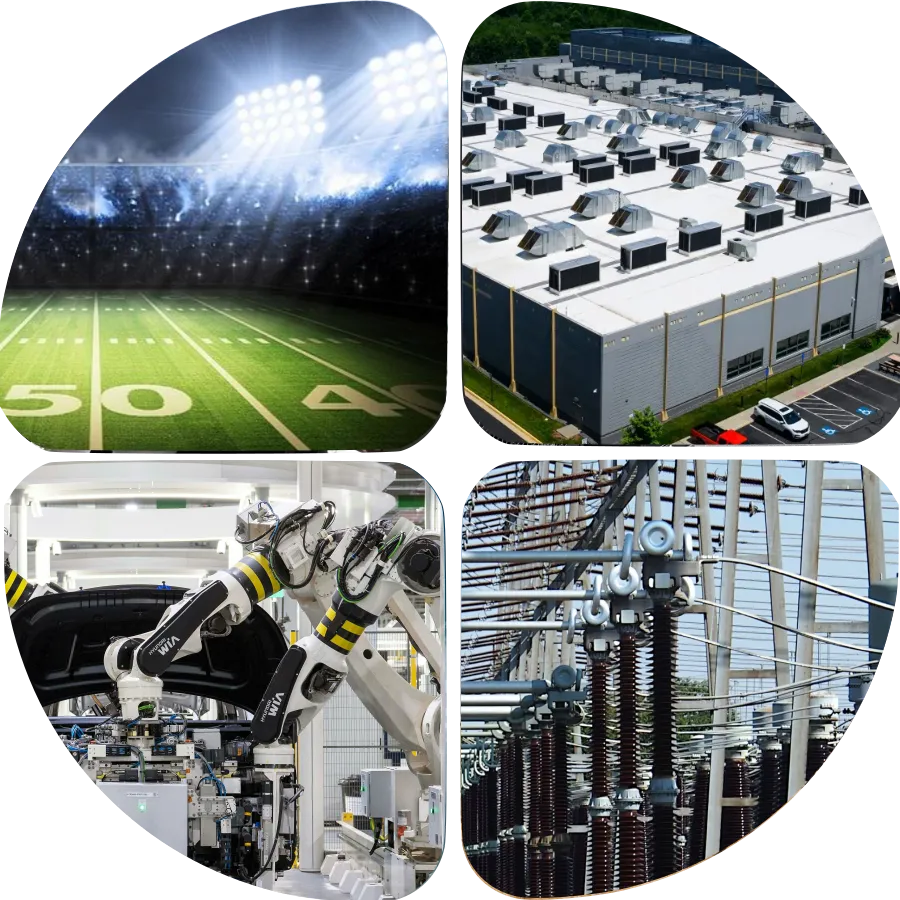

Applications of cold-forged heat sinks

Application of cold forging in heat sinks

Material Selection: Cold forging is commonly used in the manufacture of aluminum alloy heat sinks. Aluminum alloys have good thermal conductivity, are relatively inexpensive, and lightweight, making them suitable for mass production.

Forming Process:Cold forging can produce aluminum alloy materials into heat sinks with complex shapes and high precision, which can dissipate heat in the following ways:

Heat conduction: Transfers heat from a heat source (such as the CPU or graphics card) to the heatsink itself.

Thermal radiation: Heat is radiated into the surrounding air through the surface of the heat sink.

Thermal convection: By increasing the surface area of the heat sink, and in conjunction with a fan or water pump, heat is dissipated by accelerating the flow of heat from the surface of the heat sink to the air or liquid.

Examples of modern heat dissipation technology

Air cooling: Commonly found in CPU and graphics card coolers, it uses a fan to blow heat away from the heatsink fins.

Water cooling: Water or other liquids are used as heat transfer media. A water pump carries heat from the heat source to the radiator, and then a fan dissipates the heat.

Product Features

- High Thermal Conductivity: Cold-forged heat sinks are mostly made of pure aluminum (such as AL1070 and AL1050 series). Pure aluminum has a thermal conductivity as high as 226 W/m·K, which is much higher than that of ordinary die-cast aluminum alloys (about 96 W/m·K). The cold forging process makes the internal structure of the material more compact, further improving its thermal conductivity.

- One-piece molding: Cold-forged products are typically molded in one piece without riveting or welding seams, avoiding thermal resistance caused by the joint surface and facilitating rapid overall heat conduction and dissipation.

- Dense Structure:At room temperature, through high-pressure plastic deformation, the as-cast porosity, pores, and microcracks inside the material are compacted or closed, and the grains are refined, resulting in good internal density and high strength in the finished product.

- High shape and dimensional accuracy: Cold forging can achieve higher product dimensional accuracy and a smoother surface, reducing or eliminating subsequent cutting processes and achieving minimal or no cutting.

- Design flexibility: Through mold design, complex structures can be achieved, such as heat dissipation fins forming on both the top and bottom sides of the base plate to meet different heat dissipation requirements.

- Lightweight Design: Compared to other manufacturing processes (such as die casting), cold-forged radiators can be lighter, contributing to the overall lightweight design of the device.

- High production efficiency: Fewer processing steps, easy for mass production, and good cost performance.