Custom CNC precision parts machining

Custom CNC precision parts machining

Haoyang Huifeng Co., Ltd. has always focused on precision machining of various non-standard parts and customized products. We have accumulated rich experience in providing processing services for industries such as radiators, communications, automobiles, and automation. Our main business includes the machining of automation components, precision radiator parts, and precision new energy parts. We provide customers with stable and reliable products and services with excellent quality and professional service. Welcome to contact us for inquiries.

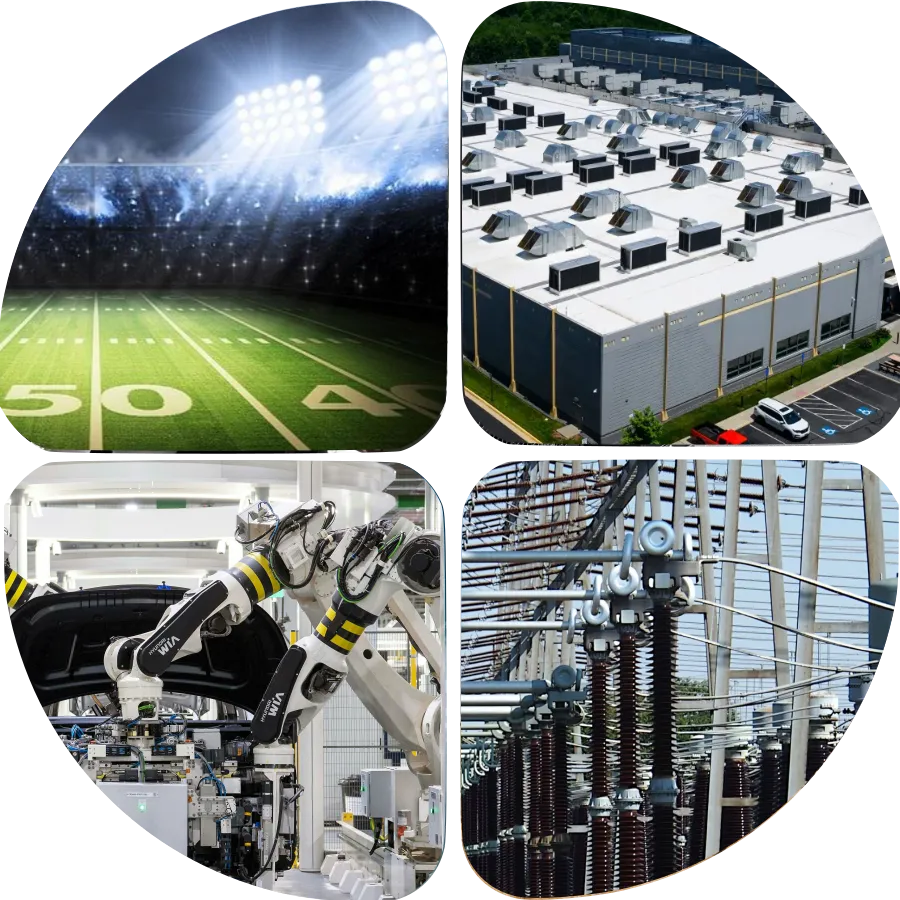

Application scenarios of CNC precision parts

Automotive: Production of engines, transmissions, chassis, and other complex automotive parts.

Medical Devices: Manufacturing precision surgical instruments, electronic casings, prostheses, implants, and other medical components.

Electronic Products: Precision parts used in the production of circuit boards, precision housings, and various electronic devices.

Prototyping: Rapidly develop and validate prototypes of new products.

Consumer Goods: Manufacturing high-precision consumer goods such as custom watch parts and mobile phone accessories.

Energy: Used in the manufacture of components for wind turbines, oil/gas equipment, and other related products.

Industrial Equipment and Automation: Precision components required for the production of industrial robots and various industrial equipment.

Product Features

- High Precision and Tight Tolerances: CNC machine tools perform machining according to preset programs, enabling the movement of the cutting tool to be precise to the micrometer level. This high precision and controllability result in extremely small tolerances in the machined parts, meeting the stringent requirements of precision equipment and high-end manufacturing.

- High degree of automation and consistency:The entire processing is controlled by computer programs, greatly reducing human intervention and operational errors, and improving production consistency. All products in the same batch can maintain the same size and quality standards.

- Powerful Capability for Machining Complex Shapes: CNC technology can easily manufacture complex geometries and intricate details that are difficult to achieve by hand, such as three-dimensional surfaces, complex grooves, and gears. The application of multi-axis machining centers further enhances this flexibility.

- High Efficiency and Cost-Effectiveness: Automation and high speed mean faster production cycles and lower labor costs. In many cases, CNC machining can complete multiple machining steps in a single setup, improving overall efficiency.

- Material versatility: CNC machining is not limited to metals; it can also be used for a variety of materials such as plastics, ceramics, and composites. Different materials can be processed by selecting appropriate cutting tools and machining parameters.

- Adaptability and Customization: By modifying the processing procedures, production of different products can be quickly switched, offering great flexibility. This makes small-batch customization or small-volume production more economical and feasible.