Finned radiator component manufacturing

Finned radiator component manufacturing and processing

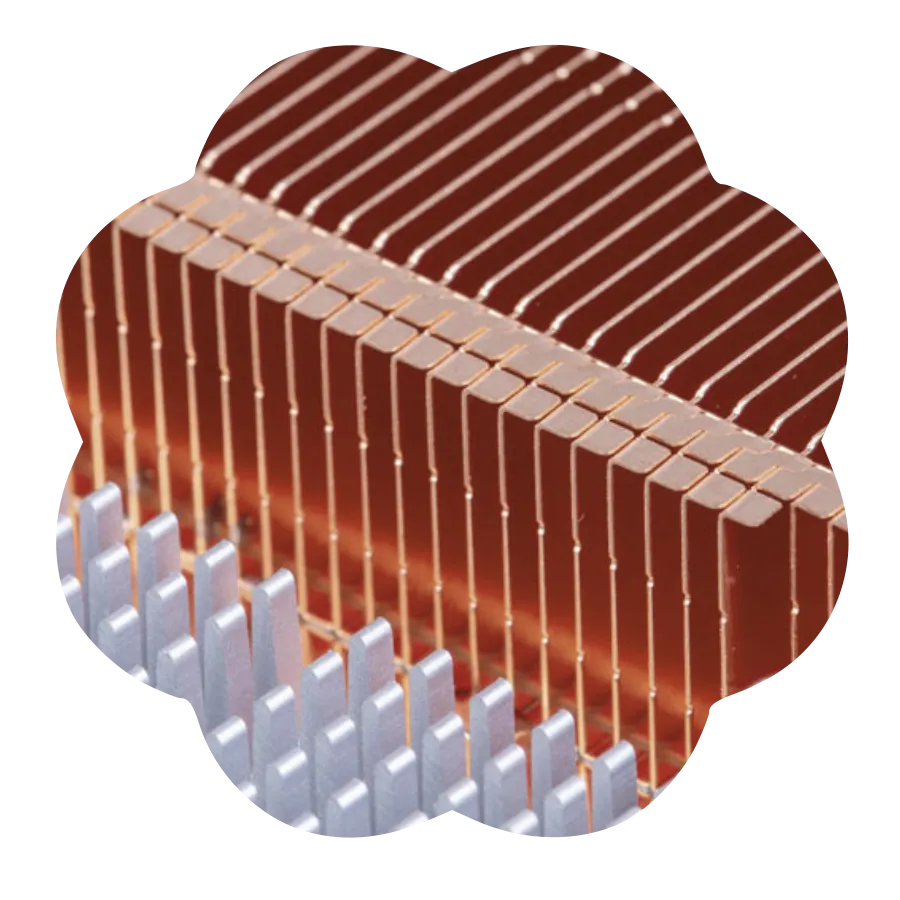

Pin-fit radiators, a traditional manufacturing process for high-power heat sinks, typically use a tight-fitting riveting method. However, this can lead to potential heat dissipation risks such as gaps and loosening of the pins. To address this issue, we have innovated and introduced several new media connection processes, including high thermal conductivity epoxy resin bonding, brazing, and soldering. These methods significantly improve the reliability and stability of heat dissipation, avoiding potential risks. Pin-fit radiators feature: dense pins, small inter-pin spacing, flexible height and width for various applications, small size, and light weight, making them an ideal choice for high-power device heat sinks.

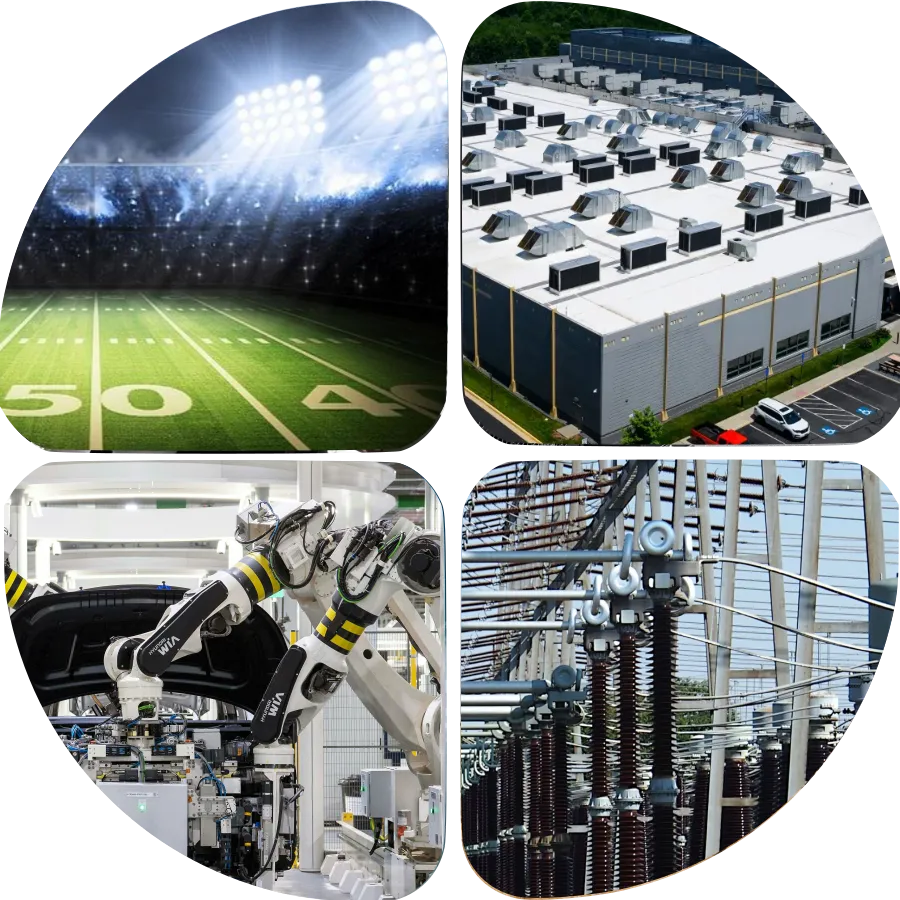

Application scenarios of finned heat sinks

High-power semiconductors: IGBT components, power rectifiers, and high-power semiconductors are the main applications of interposer heat dissipation because they generate a lot of heat during operation and require efficient heat dissipation solutions.

Industrial and Automation Equipment: Welding equipment, electrical equipment (such as traction control motor drives), laser systems, factory automation equipment

Power and Energy:Uninterruptible power supply (UPS) systems, renewable energy equipment (such as inverters)

Other electronic devices: Thermoelectric modules

Product Features

- High-efficiency heat dissipation:By increasing the number of vertically arranged heat dissipation fins, the contact area with the air is significantly expanded, thereby greatly improving heat dissipation efficiency.

- Compact Structure: The closely spaced heat sinks give the radiator a compact overall appearance, making efficient use of space.

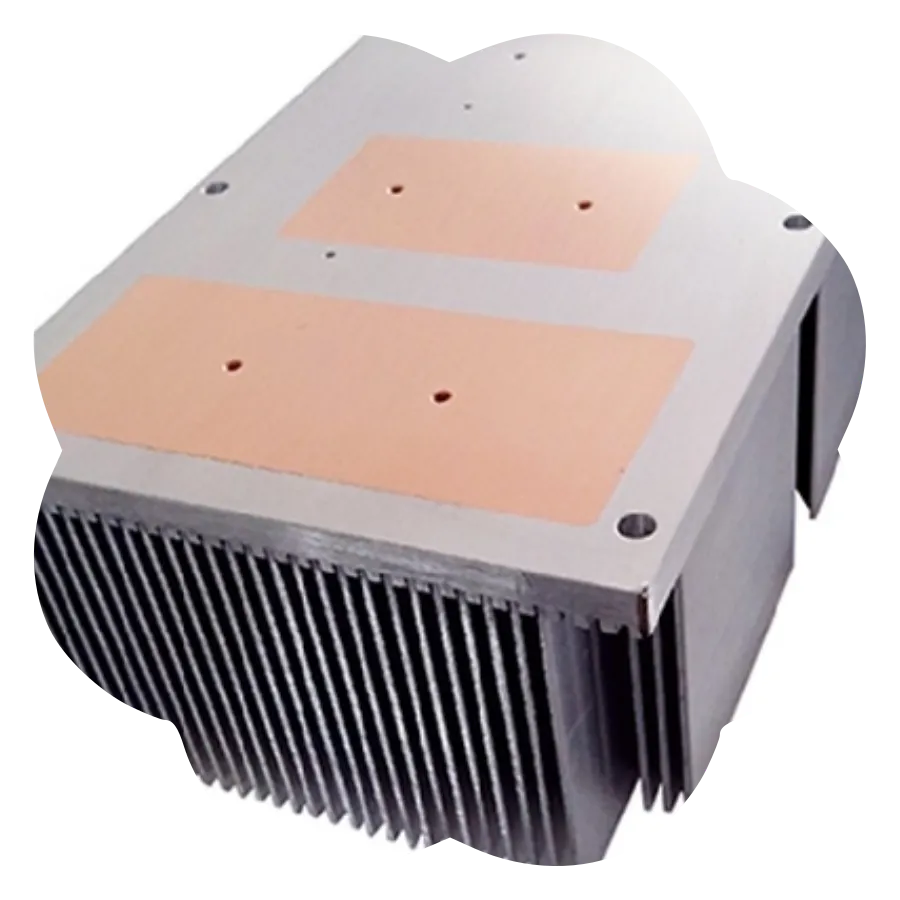

- Superior Materials: Materials with good thermal conductivity, such as aluminum alloys or copper, are typically used. Aluminum, in particular, has a thermal conductivity more than three times that of steel, exhibiting excellent thermal conductivity, pressure resistance, and metallic thermal strength.

- Lightweight: In particular, aluminum finned heat sinks are much lighter than traditional materials such as cast iron, which helps to reduce the overall weight of the equipment.

- Easy to install: The structure is simple and easy to operate and install.

- High design flexibility: The shape and size of the heat sink can be customized according to specific application needs to meet the heat dissipation requirements of different devices.

- Environmentally friendly and energy-saving: The production process of aluminum heat sinks produces less pollution, which aligns with the development trend of "lightweight, high efficiency, environmental protection and energy saving".

- Diverse surface treatments: The surface can be treated with anodizing, electrostatic powder coating, etc., to increase corrosion resistance, while improving thermal radiation performance and aesthetics.

- Customizability: Thinner and denser fins can be achieved through cutting processes, or copper-aluminum combination, tooth-forming technology, etc., to further optimize heat dissipation and avoid interface thermal resistance issues.