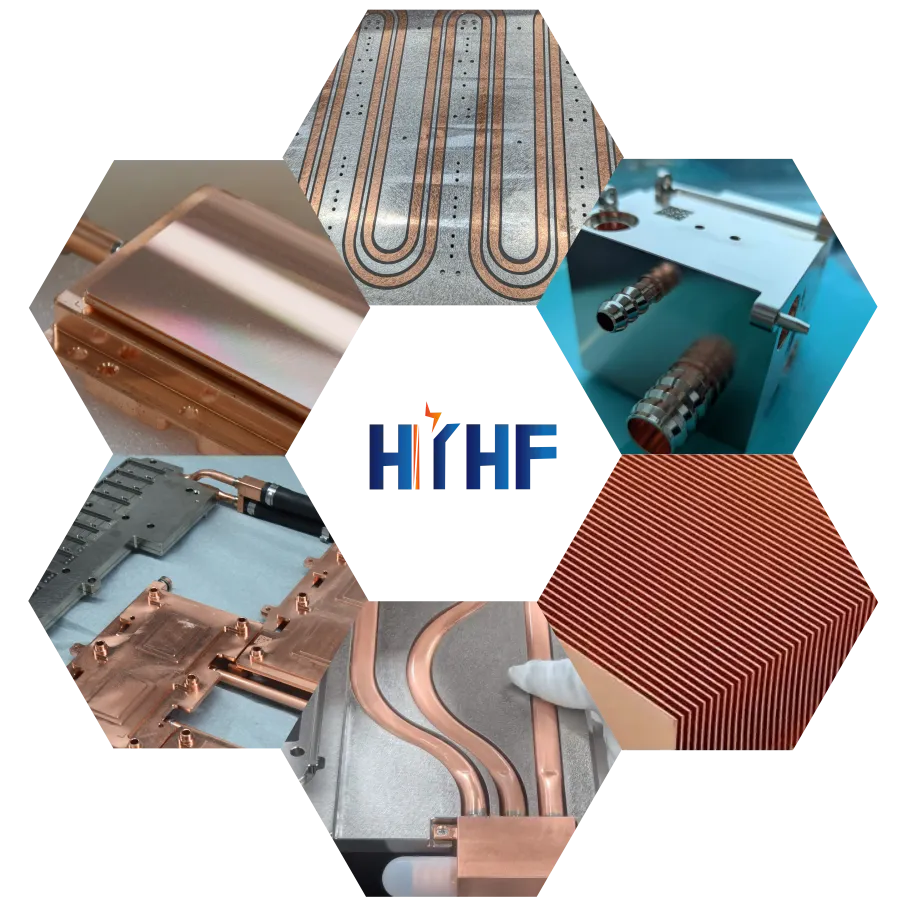

Heat pipe radiator component manufacturing

Heat pipe radiator component manufacturing and processing

A heat pipe radiator is a passive heat transfer device that can effectively transfer heat to other areas. Operating based on the principles of phase change and fluid dynamics, it can rapidly transfer heat energy.

Heat pipes are highly efficient at heat transfer, transferring large amounts of heat through phase change exchange. They can rapidly transfer large amounts of heat from a heat source over long distances via the pipe. Heat pipes are primarily used in electronic devices such as laptops, mobile phones, and game consoles to effectively transfer heat generated by processors and graphics cards. They can also be used in systems such as CPUs, GPUs, and LEDs, or in solar energy and aerospace thermal control.

Application scenarios of heat pipe radiators

electronic devices

Computers and Servers: In high-heat-generating components such as CPUs, GPUs, and servers in desktops and laptops, heat pipes can efficiently conduct heat to heat sinks, maintaining stable equipment operation.

Mobile phones and tablets: Used to improve the heat dissipation performance of mobile devices and prevent overheating.

Other electronic products include semiconductor devices, IGBT modules, and optical communication equipment.

Aerospace

Satellites and Space Stations: Heat pipes are an important component of their thermal control systems, enabling them to transfer heat generated by the equipment to heat dissipation surfaces in a vacuum environment, ensuring that the equipment can operate normally in extreme temperatures.

Rocket: Used for temperature control of equipment inside spacecraft.

Industrial sector

High-power equipment: Used in high-power lasers, power equipment (such as IGBT modules), and other high-heat industrial equipment.

Other high heat dissipation requirements

Product Features

- High thermal conductivity (“thermal superconductor”)

Heat pipes utilize the latent heat of phase change of the working fluid to transfer heat. Their thermal conductivity far exceeds that of any known metallic material, hence the nickname "thermal superconductor." They can achieve astonishing heat transfer volumes even with extremely small temperature differences.

- Approximate isothermal operation

The temperature gradient inside the heat pipe is very small, which can maintain a good isothermal environment between the heat source and the heat dissipation end, ensuring that heat is transferred quickly and efficiently from the evaporation end (heat source side) to the condensation end (heat dissipation side).

- No external power or moving parts required

Heat pipes rely on internal pressure differences to drive the circulation of the working fluid, eliminating the need for additional external power or mechanical moving parts. This significantly improves system reliability while enabling noiseless operation.

- High reliability and long lifespan

Because there are no moving parts and each heat pipe is permanently sealed, it has a long service life and cannot be damaged naturally during use except by human intervention. It usually does not require maintenance or upkeep.

- High design flexibility

Heat pipes can be combined with other cooling methods (such as fans and heat sinks) to further improve system performance. Their compact structure and large heat transfer area per unit volume make them easy to integrate into space-constrained devices, such as laptop CPU cooling modules. Furthermore, the flexibility of heat pipes provides design flexibility, but excessive bending can negatively impact performance.

- High heat transfer efficiency

Heat pipe heat exchangers can use a counter-current design, and the heat pipes themselves have a very small temperature drop, resulting in high heat exchange efficiency. Even when the temperature difference between the cold and hot air flows is small, a certain degree of heat recovery efficiency can still be achieved.