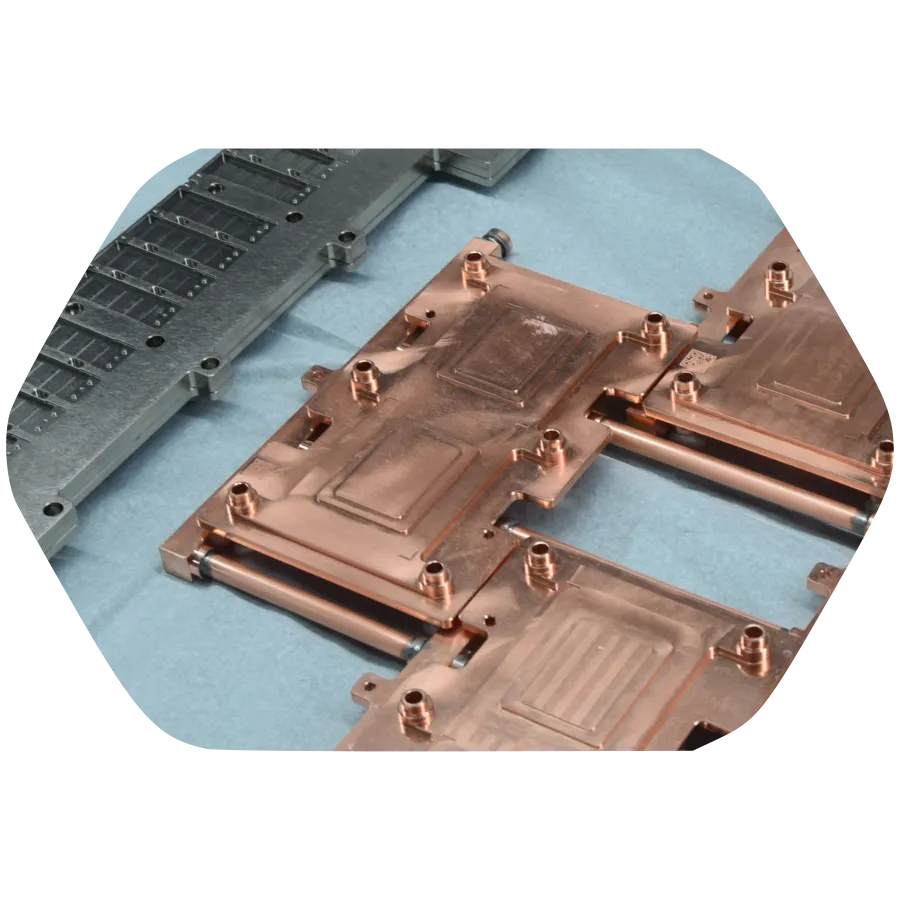

Liquid cooling plate component fabrications

Liquid cooling plate component fabrications

Cold plates transfer heat directly from components or equipment to the circulating liquid coolant, effectively dissipating heat to maintain optimal temperatures.

Liquid cooling plates are primarily used in power electronics control, conversion, drive, and signal transmission, as well as in the new energy sector (heat dissipation for new energy vehicle power batteries, UPS and energy storage systems, large servers, large photovoltaic inverters, SVG/SVC, etc.). Liquid cooling technology offers high efficiency, low noise, and low-temperature operation, making it the preferred thermal management method when space constraints and heat dissipation issues are the biggest limitation to ideal product development. We have extensive experience in water-cooling system R&D and water-cooled plate manufacturing, and can provide comprehensive liquid cooling solutions. We offer free design services for liquid cooling plate/water-cooled plate thermal design, structural design, water channel connection, and one-stop support.

Application scenarios of liquid cooling plates:

Computer chips: Cold plates can effectively reduce chip temperature, improve chip performance stability and extend device life, and effectively cope with the high heat dissipation requirements brought about by AI computing power.

High-power LEDs: Cold plates can help reduce the operating temperature of LEDs, improve photoelectric conversion efficiency, and extend the lifespan of LEDs.

Aerospace Electronic Equipment: Cold plates can help control equipment temperature, ensuring that the equipment can still operate normally in extreme environments, thus improving equipment reliability and safety.

High-power lasers: The cold plate can effectively dissipate heat, prevent the laser from overheating due to excessive power, and ensure the laser's working stability and long-term operation.

Semiconductor cooling field:High-power semiconductor cooling chip heat dissipation.

Product Features

- High thermal conductivity: It has excellent thermal conductivity and can quickly transfer the heat generated by electronic components to the cold plate, thereby reducing the operating temperature of electronic components.

- High-efficiency heat dissipation:The cold plate employs a special structural design that increases the heat dissipation area and improves heat dissipation efficiency. Furthermore, the surface of the cold plate undergoes special treatment, providing excellent thermal conductivity and anti-oxidation properties.

- Multifunctionality: The cold-plate design is simple and easy to install. It can be customized to meet different application scenarios and requirements, offering high flexibility and applicability.

- High reliability: Made with high-quality materials and advanced manufacturing technology, it has a long service life and stable performance, ensuring stable system operation.

- Heat conduction uniformity: High-performance cold plates can maintain high heat conduction efficiency and achieve uniform heat conduction, reducing heat accumulation and temperature gradients.