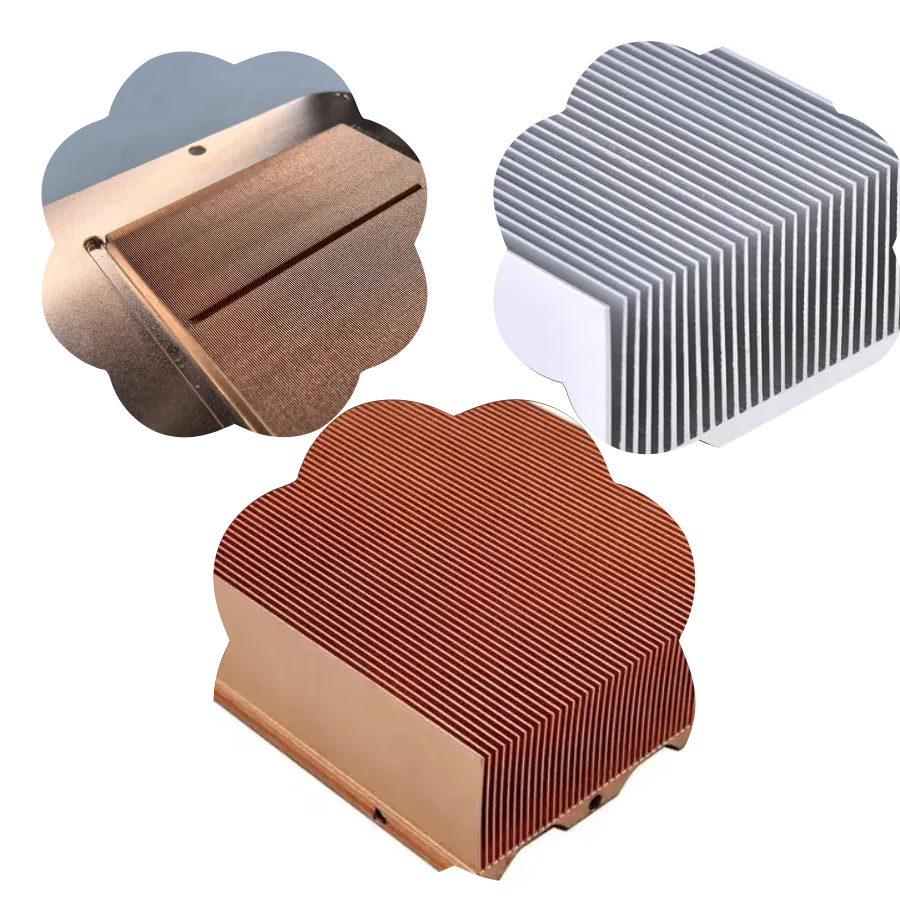

Skived fin heat sink fabrication

Skived fin heat sink fabrication

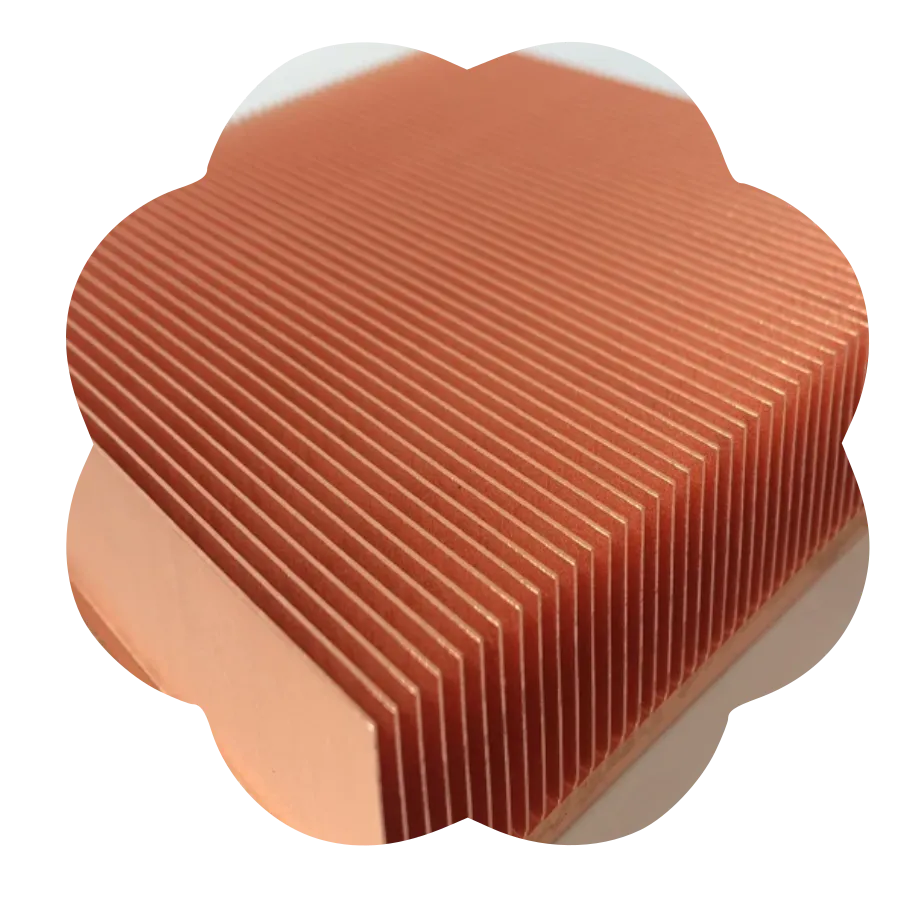

The skived fin heatsink is formed in one piece by using a finning process, where the fin and the base plate are integrally molded without any joints, allowing for highly efficient heat dissipation through conduction.

Application scenarios of skived fin heatsink

Electronic equipment: Computer CPU coolers, LED lights, inverters, communication products

Automotive Industry: Engine Cooling System

Aerospace: Heat dissipation for aircraft

Energy Industry: Applied to photovoltaic equipment

Product Features

- One-piece molding, stable performance: The spade-shaped radiator is molded in one piece, eliminating the risk of loosening or falling off due to splicing, ensuring stable heat dissipation performance.

- High thermal conductivity: It maintains 100% thermal conductivity of the original profile and will not be lost due to processing technology.

- High-efficiency structure: It can achieve ultra-thin heat sinks, ultra-small pitch and ultra-high heat dissipation structure, increasing the heat dissipation area.

- Suitable for high power and large size: The tooth-shaving process is particularly suitable for producing large-size, high-power heat sinks, which are commonly used in photovoltaic inverters, wind power converters, electric vehicle controllers, etc.

- Cost Advantage: Suitable for mass production and without mold costs, it has a low cost advantage.

- Flexible Design: It can be combined with other heat dissipation technologies such as heat pipes and water cooling plates, and can be designed according to the characteristics of different motors to improve performance and reduce costs.

- Wide range of materials: Aluminum or copper profiles can be used as the base material.