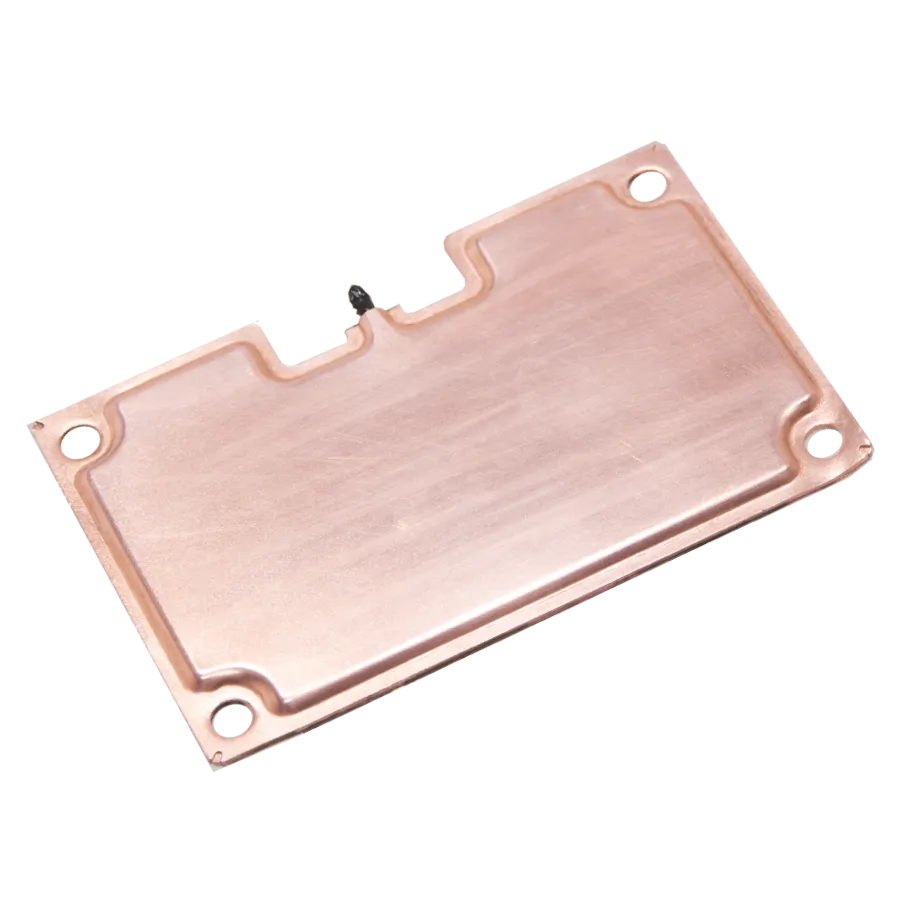

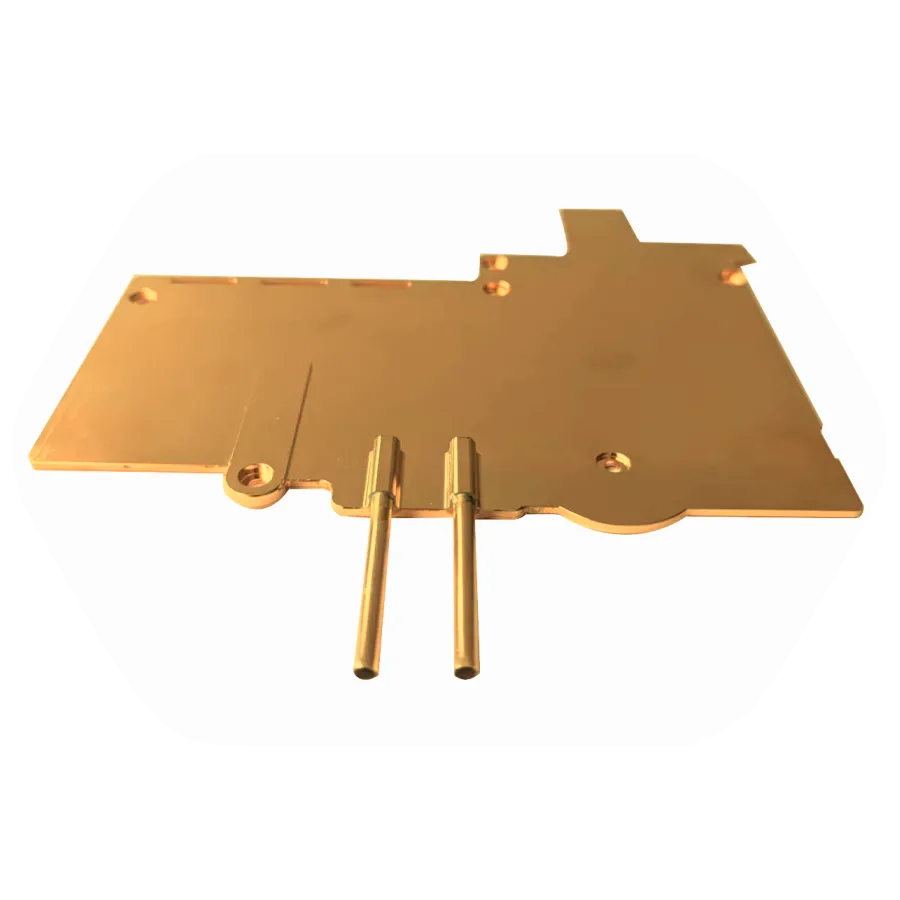

VC vapor chamber heat sink manufacturing

VC vapor chamber heat sink

A vapor chamber is an advanced cooling technology, operating on the same principle as a heat pipe. It is primarily used in scenarios requiring larger surface areas for more uniform heat dissipation under greater heat loads. While flat in appearance, it demands high sealing performance; its thin structure is ideal for cooling high-power electronic components such as CPUs and GPUs in modern electronic devices and high-performance computing environments.

Application scenarios of VC heat exchanger

Electronic Device Cooling: Heat sinks are particularly suitable for devices that generate a lot of heat but have limited space, such as laptops, smartphones, and high-end graphics cards (GPUs). Their two-dimensional heat dissipation capabilities and slim design allow for rapid and efficient heat transfer from multiple angles, ensuring stable device operation.

Servers and Workstations: In high-performance computing devices such as servers and workstations, vapor chambers are used to dissipate heat from critical components such as CPUs and GPUs, helping to maintain the devices within a safe operating temperature range and extend component lifespan.

Communication equipment: Can be used in scenarios requiring efficient heat dissipation, such as 5G base stations and high-end telecommunications equipment.

New Energy: In components such as electronic control units and battery management systems of new energy vehicles, heat exchangers can be used for heat dissipation.

Other industrial applications: It can also be applied to industrial production scenarios such as heat dissipation of semiconductor cooling chips.

Product Features

- Extremely High Thermal Conductivity: The vapor chamber utilizes the evaporation and condensation phase change process of the working fluid (such as deionized water, acetone, etc.) to transfer heat. Its effective thermal conductivity is much higher than that of traditional metal materials (such as copper or aluminum), enabling it to quickly conduct heat from the heat source to the entire surface of the plate.

- Excellent temperature uniformity:The vapor chamber can evenly distribute heat across the entire surface area, significantly reducing hot spots and achieving excellent temperature uniformity, thereby optimizing heat sink performance and protecting electronic components.

- High-efficiency heat diffusion: As a planar heat pipe, a vapor chamber can diffuse high heat density or heat load over a large area, making it ideal for handling concentrated heat generated by high-power electronic devices.

- Design flexibility: The heat spreader can be made flat, ultra-thin (as thin as 0.23 mm) or complex custom shapes to fit the structural and space constraints of different equipment.

- Lightweight Design: Despite its powerful performance, the vapor chamber has a relatively compact structure and is lightweight, which helps to achieve a lightweight design for the equipment.

- Reliability and Durability: Heat spreaders are typically made of highly thermally conductive materials such as copper. Their internal vacuum-sealed working chamber and capillary structures (e.g., sintered cores, mesh cores, or grooved cores) ensure long-term stability and reliability.

- Improved System Performance: By maintaining optimal temperature, the vapor chamber helps prevent devices from throttling due to overheating, thereby improving battery life and ensuring smoother application operation.